|

All loose propellers have shown

signs of burning on the hub mounting face, sometimes accompanied

by bolt hole and/or counter bore elongation, indicating relative

motion between the propeller hub faces and contacting flanges.

Maintaining proper bolt torque is the most important

maintenance item for a wooden propeller. Loss of proper bolt

torque will result in the decrease or loss of hub compression and

thus the loss of drive friction between the propeller and mounting

hub face and the engine or spool drive flange.

At this point the

drive torque is transferred only by the propeller bolts and/or

flange drive bushing, which will then begin to elongate the bolt

holes and/or counterbores in the mounting face of the wooden

propeller and can cause cracking in the hub.

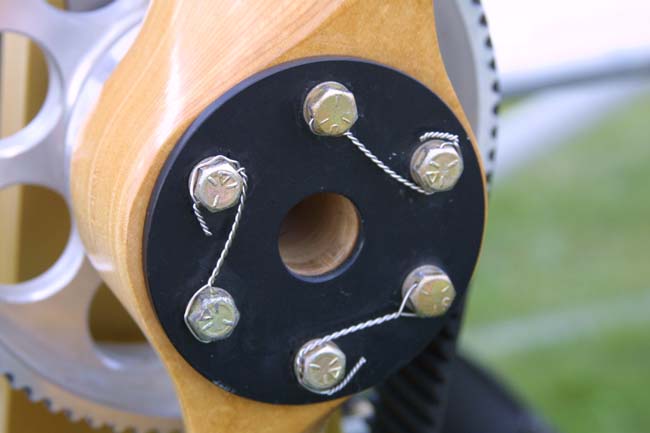

The propeller bolt

torque must be carefully applied and checked periodically in order

to maintain adequate hub compression. Do not torque above the

recommended levels as this will crush the wooden hub, breaking its

moisture seal and slightly reducing the drive-torque capacity of

the installation.

Propeller Bolt Torque Maintenance:

The main factor that leads to the loss of propeller bolt torque

is the variation of wood hub thickness with long term

environmental changes. Propeller bolt torque should be checked

according to the following schedule:

1. Stabilization Period – When installing a propeller,

check the propeller bolt torque after first flight, then recheck

every 10 hours OR 10 days, whichever comes first, until the torque

stabilizes. The torque should be completely removed and then re-torqued

to the recommended values using the pertinent installation

instructions.

2. After Stabilization Period – Once the propeller bolt

torque has stabilized, a torque check should be performed every 50

hours or annually.

3. Environment Changes – Should the operating

environment change significantly in temperature and/or humidity

for a long period of time, the propeller should undergo another

stabilization period.

Additional Installation Tips

Spinner or Spacer Installations: For propeller installations

that use spinner bulkheads or spacers mounted in-between the

propeller and mounting flange, ensure that both faces,

bulkheads/spacer, are smooth and clean.

Testing has found that painted surfaces provide the greatest

drive friction and larger safety margin if hub compression is not

maintained.

Installation Hardware: Ensure that all threads on propeller

attaching bolts, lock nuts or drive bushings (where applicable)

are clean and dry. Any lubricants on the threads can result in

over-tightening and possible crushing of the wood hub.

Wood propellers have been installed on hundreds of thousands or

aircraft over the years with excellent service histories.

Following the maintenance procedures above will help ensure safe

operation of your wooden propeller.

|