Bing 54 carburator update, Bing 54 carburator needle

and clip update.

|

|

|

|

|

|

|

|

|

|

|

|

| Bing 54 carburator needle and

clip update. |

|

Aircraft:

All ultralight aircraft using the Bing 54 carburator used on Rotax and

Hirth aircraft engines. |

|

|

Incident Report:

AAIB Bulletin No: 12/98 Ref: EW/G98/07/25 Category: 1.4

Aircraft Type and Registration:

Rans S6-ESD XL, G-MZBD

No & Type of Engines:

1 Rotax 503 piston engine

Year of Manufacture:

1996

Date & Time (UTC):

19 July 1998 at 1700 hrs

Location:

Sittles Field, Nr Lichfield, Staffordshire

Type of Flight:

Private

Persons on Board:

Crew - 1 - Passengers - 1

Injuries:

Crew - None - Passengers - None

Nature of Damage:

Significant damage to the landing gear and cockpit floor

Commander's Licence:

Private Pilot's Licence

Commander's Age:

42 years

Commander's Flying Experience:

226 hours (of which 25 were on type)

Last 90 days - 32 hours

Last 28 days - 20 hours

Information Source:

Aircraft Accident Report Form submitted by the pilot telephone

enquiries with owner, aircraft repairer and other agencies.

The pilot reported that during the final leg of a cross-country

flight,

whilst flying at approximately 1000 feet amsl, the engine RPM

decreased

from 5,800 to approximately 3,800 and the unit began to run very

roughly.

Various throttle positions were tried, none of which improved the

situation. After some 30 seconds the engine stopped completely, the

height

by then being 750 feet agl or less.

In view of this low height, no attempt was made to re-start the

engine.

The pilot judged that the only safe landing field available was

directly

beneath the aircraft and accordingly he commenced a steep right-hand

turn

through 360 degrees to position the aircraft into wind and facing up

the

local slope. Unfortunately, after straightening out the aircraft,

insufficient airspeed and height remained to enable the aircraft to

round-out into the uphill flight-path necessary for a landing. The

aircraft stalled whilst about 10 feet agl.

Examination of the engine subsequently revealed that a needle in the

jet

of one of the carburettors had detached and fallen into the jet area.

It

detached as a result of breaking in the plane of the locating groove

after

severe machining type wear had been inflicted as a result of

continuing

rotation of the needle relative to its mounting circlip. This problem

has

been encountered in the past; it occurs under certain conditions of

vibration and resonance. It led to the fatal accident of the similarly

powered Colb Twin-Star, G-MWWF, in 1994, see AAIB Bulletin 11/94. As a

result of that accident, the AAIB made the following comments and

recommendation to the CAA:-

"The cause of the partial engine failure was that the needle on

the rear

carburettor had worn through at the circlip and had dropped into the

carburettor jet, restricting the flow of fuel to the rear cylinder.

The

needle was retained in position by a circlip which was spilt at the

apex

of the hole holding the needle; the edges of the split had 'machined'

away

the groove in the needle as it rotated under the forces generated by

vibration. This problem is well known and both the UK distributor and

the

manufacturer (Rotax) have issued safety bulletins calling for a 50

hour

inspection of the needle and an ultimate life of 150 hours.

Rotax are developing a modification for new production which will

introduce an 'O' ring to each side of the circlip to prevent the

needle

rotating. The modification is due on the production line at the end of

the

year. It is therefore recommended that:-

94-35 The CAA require that the modification to the carburettor needle

fixture on Rotax engines be made retrospective and mandatory, and that

in

the meantime the 50 hour check be also made mandatory."

The CAA did not accept this recommendation. Their reasons were stated

in

their document 'Follow-Up Action On Occurrence Report ' No F30/94.

The modification ultimately engineered by the manufacturer is slightly

different from that described above. It has now been available (at

minimal

cost) for retrospective installation for approximately 18 months. It

is

installed on current production engines, although the fact that

suppliers

and builders of kits frequently store engines for extensive periods

results in new aircraft continuing to come into use with engines which

may

have been built before the modification became part of the production

standard.

The aircraft involved in this accident is understood to have completed

49

hours total flying at the time of the accident.

|

UPDATE

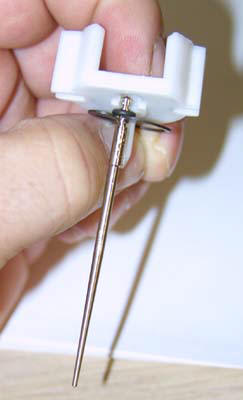

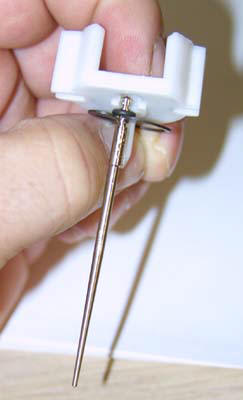

This update prevents wear on the

needle and clip. The update requires the purchase of part #831-715 a rubber 0 ring which

fits on to the top of the needle, and the installation of a NEW style retaining cup part #

827-347. The new retaining cup has a cut out for the rubber O ring which puts pressure

down on the clip and needle to prevent them from turning and wearing.

| New style retaining cup part # 827 347 - $15.95

|

|

| New O ring which can be installed

on older style needles

part # 950 430 - $3.95 |

|

| New style clip part # 963 500 - $8.75

|

|

| |

|

|

|

|

Updated needle, clip, O ring and cup |

This is the new style of clip which can be used

with the new rubber 0 ring and retaining cup.

Click here for a quick way to

check your needle and clip!

Click here for Rotax update in pdf format

|

|

|

|

|

|

|

|

|

|

Ultralight Aircraft News.ca Web Magazine EMAIL for l Information.

No part of this

publication may be copied or distributed, transmitted, transcribed,

stored in a retrieval system, or translated into any human or computer

language, in any form or by any means, electronic, mechanical,

manual, or otherwise, without written permission of Ultralight Aircraft News.

By copying or paraphrasing the intellectual

property on this site, you're automatically signing a binding contract

and agreeing to be billed $10,000 payable immediately. Copyright Ultralight Aircraft News.ca

|