|

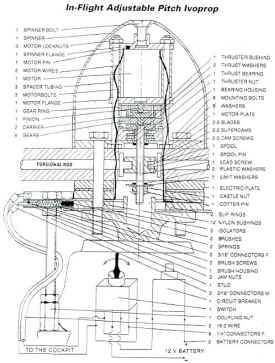

The IVOPROP operates on a COMPLETELY UNIQUE adjustable

pitch system that allows for substantially less hardware and rotating mass

than any other ground pitch adjustable prop. The unique pitch adjustment

design operates on the principle of twisting the blades through the chromoly alloy steel torsional rod cast inside the blade. The outer end of

the torsional rod is firmly anchored inside the outer blade section. The

round torsional rod is capable of rotating inside the blade, except for

the outer end. The hub ends formed into square shape. pitch adjustment

design operates on the principle of twisting the blades through the chromoly alloy steel torsional rod cast inside the blade. The outer end of

the torsional rod is firmly anchored inside the outer blade section. The

round torsional rod is capable of rotating inside the blade, except for

the outer end. The hub ends formed into square shape.

Both models utilize the same carbon / graphite fiber blades

with stainless steel leading edges. The blades are capable of pitch change

3 to 17 degrees on the tips or inches of helix advancement from 18"

to 52".

The ability to change the pitch in flight is as significant

for the airplane pilot as for the driver of a car to shift gears in the

transmission

These results in substantial savings in fuel, engines wear

and noise.

• Pilot

controls the pitch trough the toggle switch mounted in the cockpit.

Pressing the toggle switch one way sends electric current trough the

graphite brushes to the slip rings and finally to the electric motor.

• Depressing

the toggle switch the other way reverses the polarity of current and the

rotation of electric motor. The pitch changes operation is similar to the

power windows in an automobile. As long as you hold the switch in one

direction- the pitch changes in that direction and you observe the result

on your RPM meter.

• Torque

from the electric motor is multiplied in a two-stage planetary gear drive,

which turn the lead screw.

• Lead

screw is supported by a thrust bearing and converts it's rotary motion

into axial movement of the spool. •

The spool is linked to the super cams, which turn the torsional

rods. Torsional rods transmit the movement from the center of the prop to

the outside section of the blade. This causes the blade to twist therefore

changing the pitch in the same manner as the ground adjustable pitch

system. • Total time

required for full range of adjustment is about 5 seconds.

• Movement

of the spool can be restricted each way by inserting washers on the lead

screw. This limits maximum and minimum pitch and prevents engine

over-revving.

• Mounts

directly to any rotax gearbox, "B", "C" models. Can be

adapted to VW, Subaru, Hirth, Arrow, and smaller Lycoming and continental

engines.

• Older

models Ivoprop ground adjustable props can be convert to In-Flight

Adjustable System by means of retrofit kit. Torsional rod must be offset

toward the leading edge of the prop. Early model props with the torsional

rod located in direct center of the blade can not be converted.

• In-Flight

adjustable hub comes assembled with instructions on how to use it.

•

Total weight of 3-blades 72" diameter In-Flight Adjustable

IVOPROP including wire harness, spinner, control switch, mounting

hardware, and the circuit breaker is I Olbs.

Insert the mounting bolt with

the washer through the motor plate in one of the boltholes closest to the

two motor wires.

Insert one blade on the mounting

bolt. Flat airfoil side towards the electric motor for pusher. Curved

airfoil side toward electric motor for tractor.

Rotate the blade so that the

super cam goes into the groove in the spool. Insert second bolt through

the motor plate and blade.

Insert electrical plate (the one

without nylon bushings) on the bolts. Insert small isolator.

Insert slip ring on the bolts.

Do not push out the nylon bushings.

Bend one motor wire in right

angle radially outward on the slip ring. Insert second small isolator.

Bend second motor wire the same

way like the first one on the isolator. Insert second slip ring. Insert

large isolator.

Bolt prop loosely on the flange.

Insert remaining blade (s)

between plates and torque mounting bolts to 200 inch X Lbs.

Rotax reduction. "B ":

replace one of the 8mm nuts on the gearbox closest to the prop axis with a

coupling nut (torque 150inchXLbs.)

Screw the stud into the coupling

nut deep enough to clear the blades, and lock it with jam nut.

Rotax reduction "C ":

replace 6mm bolt on the gearbox with stud and counter torque one of the jam

nuts against the gearbox I 00inch. X Lbs.

Other than Rotax : Mount the

stud "somehow " next to the flange so that brushes will contact

slip rings Screw the jam nut on the stud, insert the brush housing and

screw the last jam nut on the stud

Position and torque the jam nuts

against brush housing so that brush on the blade side is in contact with

brush plate right next to the isolator. That way there is a maximum

clearance between brush housing and the blades.

Install switch and circuit

breaker in the cockpit in a place where you can easy reach but not

accidentally activate.

Attach 3116" connectors to

the brush housing running the wire under the stud

Attach battery connectors to the

battery. Circuit breaker wire belongs to the positive pole.

Write next to the switch

direction of the pitch change. By interchanging brush connectors you can

change the direction of the pitch change.

Example:

Pitch up RPM down Cruise

Pitch down RPM up Climb

* Caution : Brushes are brittle. Do not brake them.

Setting

Your Own Pitch Limits How

To Fly With It

The pitch change operation in

flight can be greatly simplified by restricting movement of the spool

therefore limiting the pitch change from your best climb pitch to your

best cruise pitch. Land with the prop in your best climb pitch.

Take prop off the flange. Do not

take the mounting bolts out of the prop.

Measure (with a calliper) the

distance from the spool and the end of the lead screw and write it down.

Mount the prop back on the flange.

Go flying and find your almost

best cruise pitch. Remember "almost " stands for the pitch which

will still give you a little bit of climb.

Land the prop in your

"almost " best cruise pitch.

Take the prop of the flange and

measure the distance between the spool and the end of the lead screw and

write down.

Mount the prop back on the flange

and bring it to neutral (you can hear it -no load on the electric motor.)

Take prop apart.

Insert limit washers on the lead

screw so that spool can not travel beyond your measurements.

Do not forget to insert plastic

washers on each side of the spool. Failure to do so will immediately lead

to the destruction of the gears in the planetary drive.

Note: the thickness of the

plastic washer under load is about Y2qf its original thickness.

Do the first flight in still air.

Run the prop W. 0. T on the ground and adjust pitch

offew hundred R.P.M. bellow your maximum HP R. P. M (W. 0. P. means wide

open throttle.)

Climb W. 0. T and adjust the pitch to maximum climb

rate. (Do not exceed maximum allowable R.P.M for your power plant.)

Remember your R.P.M at your best climb pitch.

After reaching cruising altitude hold W. 0. T and

start increasing pitch by short impulses until your climb rate is about

200ft/min.

Remember your W. 0. T R.P.M at this your almost

best cruise pitch.

Throttle back until your R. P. M start dropping or

until your climb is zero.

Before landing go for a moment into W. 0. T and

start decreasing the pitch by short pulses until you reach your best climb

R.P.M which you remember from the take-off

Do not change the pitch after landing. Run the prop

W. 0. T on the ground and remember your best climb R. P. M which you remember from

the take off

Before next take-off run prop W. 0. T and read your

best climb ground R.P.M to make sure that your pitch is in climb setting.

Next time you want to cruise even in a turbulent air just

use your almost best cruise R. P. M which you remember from your last flight

in order to put prop in your almost best cruise

Important:

Assume

that in-flight pitch adjustment can quit on you any time in which case the

pitch stays where it is. Therefore do not pitch prop up for cruise more

than you need to slightly climb. So you can bring your plane back where

you came from.

Do not

use pitch adjustment more than you need and always allow some time for

electrical components to cool down between cycles.

Do not

run the prop without the circuit breaker, which is supplied with it.

If you

hold the switch for few seconds after reaching the pitch limit therefore

stalling the motor the circuit breaker pops out and you have to wait

several seconds to reset it.

The

system will not run safely on regulated DC current from regular there you

need a battery. Before disassembling the prop always bring the pitch to

the neutral

Never

engage pitch adjustment only on one blade or on two blades spaced 120

degrees. Do not remove carbon deposit from brushes on slip rings.

Do not

rely on spring, which returns the switch lever to the neutral position.

If you

can not change the pitch in-flight try it in idle R. P. M or try to move

the Switch lever back and forth.

Do not

copy terrene in cruise pitch.

Even if you fly

without setting your pitch limits you still need one limit washer the

castle nut and the plastic washer.

Do not

shorten the 12'wires or circuit breaker will pop out sooner. Keep the

grease away from plastic and limit washers.

Brushes

wear much faster when wet. Therefore if you really have to fly in a rain

pitch the prop for climb, loosen the jam nut, which is against coupling

nut, turn brush housing away from brush plates and retorque the jam nut.

Make

sure that there is no electric continuity between brush and plates and the

engine frame-otherwise you could destroy your regulator-rectifier when

changing the pitch while engine is running.

After

you are done with setting the limits and the final installation seal the

gaps between the blades with silicon and install the spinner to keep the

water and dust from getting into the mechanism. Tie down or put the tape

over the brush connectors so they will not come loose in flight.

Apply

blue loctite on the spinner bolt and bolt and torque to 35 inch XLbs.

otherwise your spinner will fall off

If you

wish to secure mounting bolts- use 8mm nylon lock nuts (not supplied) on

the other side of the flange.

Use

only the hardware supplied with the prop, never drill or modify the

boltholes in the blade (s). Maintain the 200-inch XLbs. torque on the

bolts.

Make

sure that there is at least 5" of clearance between the blade

tips and trailing edge of the wing, radiator rudder, or whatever, because

the blades are design to flex-x back and forth more than wooden blades. Do

not slide your fingers along the trailing or leading edge of the blade, fibbers

may pierce your skin.

If you

wish to increase top speed or decrease cruise R.P.M., switch to a 2-blade

prop or cut the 3-blade prop to a smaller diameter using a hack saw, as

long as you cut the same length piece from each blade, the prop will

remain in balance. Do not cut the prop to less than 48" diameter.

When switching from

3-blade to a 2-blade configuration, increase the pitch about 4 degrees.

Rotax

engines develop maximum horsepower around 6500 RPM so pitch the prop

accordingly.

If you

are going to use other than skull cap type spinner make sure that there is

at least 114 " clearance between blades and cut-outs in the spinner.

If your

aircraft holds U.S. experimental airworthiness certificate you are

supposed to contact the F.A.A. FSDO before flying the aircraft. When notified,

the F.A.A. inspector can determine if procedure was major change (as

defined per far 21.93 and listed in appendix a to part 43) and if any

additional inspections or operating limitations are needed prior the flight. |