|

AIRCRAFT ENGINES SERVICE BULLETIN

CHECKING OF THE CRANKCASE ON ROTAX ENGINE TYPE 912 AND 914

(SERIES) SB-912-029 SB-914-018 MANDATORY

Engines affected All versions

of the engine type:

- 912 A up to S/N4,410.384

- 912 F up to S/N4,412.796

- 914 F up to S/N4,420.313 1.2)

Reason:

One or more of the following could result in formation of cracks

on the crankcase:

- Unapproved and untested modifications

- lmproper carburetor synchronization - Unsuitable idle speed (too

low)

- Unsuitable engine suspension I non-neutralized vibrations

- Propeller balance out of tolerance

- Friction torque in the backlash range of gearbox not within

tolerance

- Lack of maintenance

- Ground contact

- Excessive thermal strain

- Exceeding of maximum admissible engine speed

- Exceeding of maximum admissible manifold pressure Vibrations,

impacts, forces, thermal strain etc. could cause cracks on the

crankcase.

WARNING: Rectify any of the

afore mentioned without delay.

1.4) Subject Checking of the

crankcase.

1.5) Compliance

1.5.1) Engine type 912 A and 912 F - Within the next 50 hours of

operation, but at the latest by June I" 2001 the checking of

crankcase must be conducted according to the following

instructions in section 3. - Every 100 hours the checking of

crankcase must be conducted according to the following

instructions in section 3.

1.5.2) Engine type 914 F -

Within the next 50 hours of operation, but at the latest by

January Is' 2002 the checking of crankcase must be conducted

according to the following instructions in section 3. - Every I 00

hours the checking of crankcase must be conducted according to the

following instructions in section

3. 1.6) Company support information - In case of cracks on the

crankcase the complete engine must be returned F.O.B. to a ROTAX,

Authorized Distributor or Service Center. - Shipping cost, down

time, loss of income, telephone costs etc. or cost of conversion

to other engine versions or additional work, as for instance

simultaneous engine overhaul is not covered in this scope and will

not be borne or reimbursed by ROTAX,'

2.3) Material requirement per engine none. The repair has to be

performed by the engine manufacturer.

3) Accomplishment /

Instructions Accomplishment All the measures must be taken and

confirmed by the following persons or facilities: -

ROTAX-Airworthiness representative - ROTAX.- Distributors or their

Service Centers - Persons approved by the respective Aviation

Authority

WARNING: Proceed with this work only in a non-smoking area and not

close to sparks or open flames. Switch off ignition and secure

engine against unintentional operation. - Secure aircraft against

unauthorized operation. - Disconnect negative terminal of aircraft

battery (if a removal of engine is necessary).

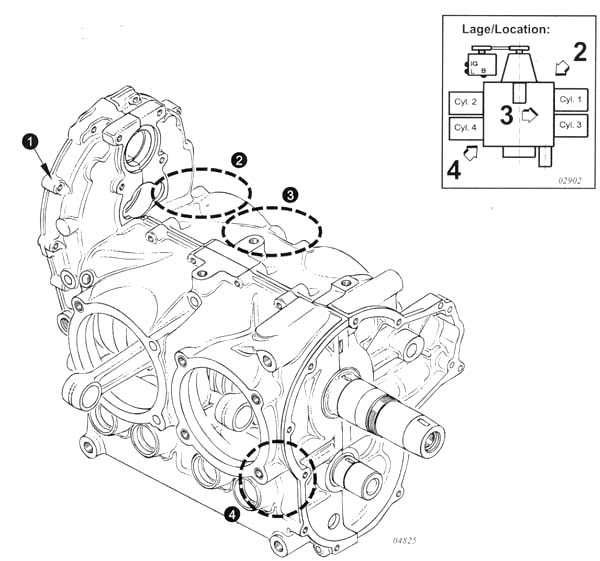

3.1) Checking of crankcase: see fig. I Visually inspect the

crankcase (1) and engine suspension for cracks in accordance with

the relevant Maintenance Manual.

NOTE: Scrutinize the crankcase

for cracks especially in the area of cylinder I upper side (2),

between cylinder I and 3 upper side (3) and cylinder 4 lower side

(4). See fig. 1.

For those engines using the

ROTAX, cooling air baffle. Visually inspect for oil leaks in area

(2) and (3). If leaks are found, then further investigation to

determine the cause of the oil leak is required. If the exact

origin of the leak can not be determined i.e. governor, then

removal of the cooling air baffle may be required. Alternative

methods of inspection may be used, i.e. bore scope , to inspect

the areas without removal of the shroud.

NOTE: If absolutely necessary,

and if only a small amount of oil leakage is found, a ferry flight

to a maintenance facility is permitted. At a massive oil leakage

replacement of engine without delay will be necessary. If cracks

are detected the

nearest ROTAX, Authorized Distributor has to be informed and if

necessary the engines has to be removed from aircraft and must be

returned to a ROTAX, Authorized Distributor. Reconnect negative

terminal of aircraft battery (after installation of engine).

3.2) Summary These instructions

(section 3) have to be conducted in accordance with compliance in

section 1.5. A

WARNING: Non-compliance with

these instructions could result in engine damage, personal injury

or death! Approval of translation to best knowledge and judgement

- in any case the original text in German language and the metric

units (SI-system) are authoritative. |