|

VENTILATING SYSTEM FOR CHALLENGER A BIT OF

THEORY |

|

|

|

|

WINTER |

SUMMER |

In winter, warm air is pushed

through cylinder cowl, into the fabric duct, then redirected by

the baffle into the heater box and down into the 4 inch aluminum

duct in the cabin.

In summer, fresh air flows into the air scoop and is redirected by

the baffle into the 4 inch round aluminum duct in the cabin.

|

|

|

|

|

WINTER TOO WARM |

SUMMER TOO COLD |

| In winter, when the cabin gets too

hot or in summer when the cabin gets to cold, a push pull control

cable moves the baffle to expel the air out. |

|

THE CHALLENGER SYSTEM |

| This system is based on the

standard heat box used before on air-cooled motor airplanes. |

|

OPERATION |

| Warm air is pushed out of the

cylinder cowl and transferred via a fabric duct to a control box.

From this box, via a remotely controlled baffle, air is directed

inside through a conduit or expelled outside. The fabric duct is

interchangeable with an air scoop. Fresh ram air caught by this

scoop is sent to the box and controlled the same way as described

before. |

|

COMPARISON |

Heaters that are attached to the

motor all have the same problem vibration! It's just a matter of

time. Our heater box sits on the two lower curved ribs under the

motor, considerably reducing the vibration. Test have shown our

heater box will survive many years before it needs servicing.

Many Challenger owners had to lower the top rib

to be able to install their heater box on the motor. This

modification alters the air flow very close to the propeller and

could add turbulence in this area, producing more vibrations and

slightly reducing the prop's efficiency.

With our system, the fabric duct uses the resilient space between

the top rib and cylinder cowl, entirely closing this gap. Many

Challenger owners had complained about the fact they had to remove

the heater box from the cowling to service the plugs.

With our system, removal of the fabric duct is easy since it's

attached to the cowling with Velcro.

By covering the cylinder cowl, warm air outlet and spark plug

area, the system collects all the warm air that's possible to

retrieve from the motor. In our test, at -10° F, we were able to

keep inside temperature to 50°F, quite comfortable. |

| |

|

THE FABRIC DUCT

Made of oil, UV and cold crack resistant fabric, the duct is

resistant to all weather.

It is also very easy to clean. Velcro at both

ends simplify its installation. |

THE AIR SCOOP

Made with the same fabric, the scoop is solidly attached to the

heater box rendering it impossible to be thrown into the prop. |

|

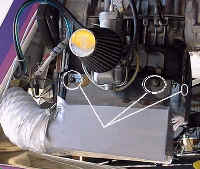

THE HEATER BOX |

Made from

composite, the heater box is light and rugged. The box sits on a

base to permit its installation directly on the lower curved ribs. Again, Velcro is

used to attach the base to the ribs.

installation directly on the lower curved ribs. Again, Velcro is

used to attach the base to the ribs.

A 4 inch flange, under the base, accepts 4 inch

aluminum tubing, with solid tubing preferred. Inside, a fabric

controlled baffle directs air out of or into the cabin via the

base flange.

The control arm and baffle frame are from

galvanized steel. The heater box can be painted with your color

choice. The complete heater box assembly weighs just under a

pound. |

| |

|

COVERS

To complete winterization, the under motor and firewall areas have

to

be

totally closed. If not properly closed, warm air will be sucked

out rendering it impossible to heat up the cabin. be

totally closed. If not properly closed, warm air will be sucked

out rendering it impossible to heat up the cabin.

We supply two covers with every kit, one for the

rear section and one to cover front part and the firewall section.

(For now these covers are adjusted to fit the

new Challenger version.) |

| |

|

CONTROL CABLE

The control cable is a push pull type. Its length, 156 inches is

more than enough to install the control knob at a convenient

location of your choice. |

| |

HARDWARE SUPPLIED

Except for the aluminum tubing, everything needed is included. The

tube can be easily bought locally for a price lower than its

shipping cost. |

| |

INSTALLATION

To make it easy to install, even with the motor installed,

self-adhesive Velcro is used. The only important task is to clean

all areas before attaching any Velcro.

The box is also clamped to the aluminum tube and

control cable rendering it impossible to fly into the prop. All

Velcro attached to the cylinder cowl is secured with pop rivets at

both ends.

Instructions are complete including several drawings.

|

|

NOTE |

Our heater box has been installed

and tested on our plane for 5 years now (over 350 hrs) and has

never needed servicing. It is a cool idea in summer and a warm

experience in winter.

|

|

MODEL: |

HBK1 for CHALLENGER I $295.00 |

|

| |

HBK2 for CHALLENGER II $295.00 |

|

| |

|

| |

installation directly on the lower curved ribs. Again, Velcro is

used to attach the base to the ribs.

installation directly on the lower curved ribs. Again, Velcro is

used to attach the base to the ribs.

be

totally closed. If not properly closed, warm air will be sucked

out rendering it impossible to heat up the cabin.

be

totally closed. If not properly closed, warm air will be sucked

out rendering it impossible to heat up the cabin.