Courtesy of http://www.tcsn.net/mswihart/mark/files/muffler_spring_stuff.txt Courtesy of http://www.tcsn.net/mswihart/mark/files/muffler_spring_stuff.txt

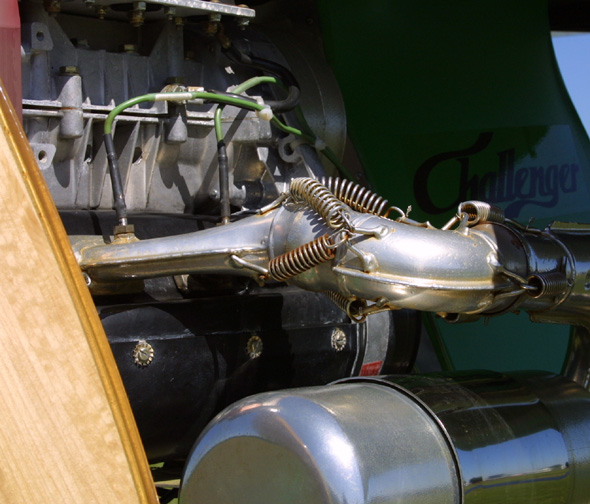

One of the least expensive and most costly items on a Rotax aircraft engine are the exhaust

springs. While they only cost about $5.00, they can cause hundreds of

dollars in damage, and possibly death, if they go through a propeller!

Your not done installing your Rotax engine until you safety wire the springs

that hold the flex ball joints together and squirt a good strip of

automotive red high temp (RTV) silicone gasket sealer down the length of

the spring.

The safety wire must pass thru the center of the spring and both ends

of the hook attachment points. The reason for the safety wire is to keep the spring out of the prop should

it break or come unhooked. The RTV

keeps the spring from vibrating which

contributes to their breaking, and holds all of the pieces together,

especially the exhaust hook TIPS. keeps the spring from vibrating which

contributes to their breaking, and holds all of the pieces together,

especially the exhaust hook TIPS.

Using pliers to install the springs causes nicks which contributes to their

breaking later. Use of a spring puller is suggested. It is tool that

looks some thing like a screw driver which has a hook on the blade end used

to grab the hook end of the spring when installing or unhooking the

spring.

They may be straight or L shape - the L gives you more

leverage.

The tool could be fabricated our of some metal banding like

they use to band crates for shipping or a flat blade screw driver by

putting a notch in the side of the flat part.

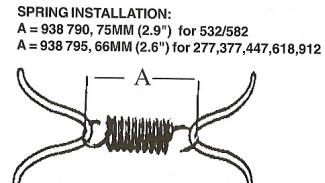

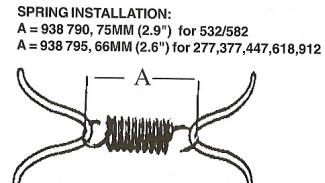

Depending upon kit manufacturer or engine supplier, the spring fastening

loops may not be installed on the exhaust system or may have to be

moved.

As an alterative there now is available a kit for fastening ball

joints together that has some advantages over the use of spring but may

eliminate need to weld loops on the exhaust pipes. Ask you kit

manufacturer if any modifications are required to standard Rotax exhaust

system.

A hockey skates-lace puller works really well for pulling the spring.

Made my tool out of a pull handle for the emergency brake in the car. Cut

it out of a junker. Leave it about 10" long. Bend a tight crook on the end

of the wire. Done, cheap and simple. The molded plastic handle makes a

great handle for pulling.

I use a short piece of safety wire tied in a four inch end to end

loop. The flexibility of the safety wire allows me to install and

un-install springs with ease. For a handle, I use a medium size phillips

screwdriver.

|

| Maybe not the neatest thing to look at but it

works. |

|

| Heat shrink installation, two globs of

silicone still need to be installed on each end of the spring hook. |

The wire may also be removed easily from springs in difficult

locations too.

If the springs are stretched more than 1/4 of an inch, they are

placing way too much load on the ball joints, creating wear that is

unnecessary. be careful when welding the tabs on the various parts.

Rather than use safety wire, I use one length of 1/16" flexible cable on

each exhaust joint that I lace through each eyelet and spring, and then

swage with a nico press.

I find this much easier, and consider it to be

stronger. I also make sure there is a bead on each spring, and at each

junction of cable and eyelet to prevent chaffing by the cable.

I also made a spring installer/removal out of an old flat blade screwdriver

I cut a short slot at a 45 degree angle into the blade. I used a cutting

blade on my small hand grinder and it took less than a minute to make.

This

tool works good, and virtually cost nothing but an old screwdriver that was

only good for opening paint cans!

Rotax

exhaust - Ball Joint Conversion Kit.

This simple bolt-on kit installs in minutes and

eliminates all custom placement and welding of standard Rotax exhaust

hooks. A matching pair of stainless steel half brackets surround the

existing exhaust pipe and are secured with AN fasteners and hi-heat

lock nuts.

AN3 bolts and SS springs tension the brackets to provide a firm yet

flexible joint. Also eliminate the large diameter springs that can

break and strike prop.

Sold in kits per joint.

|

Click here for more information. |