|

SYNOPSIS

The float equipped Challenger II was conducting a take-off from

a small lake into a 15 mph wind. Immediately after lift-off at

full power (6300 rpm) the tachometer rpm began fluctuations of

about two hundred rpm above normal take-off rpm. The rpm increased

momentarily and would then return to slightly above normal

take-off values. The fluctuations lasted about 2 seconds followed

by a sudden and complete loss of thrust and an engine over-speed

in excess of 7000 rpm.

The aircraft was accelerating through about 42 mph in a shallow

climb attitude at a height of about 30 feet and in a high drag

(take-off flap) configuration when the thrust failed. The aircraft

immediately entered the stall regime and began to mush towards the

lake surface at a steep angle that resembled a helicopter

auto-rotation. The pilot was able to control a slight nose-up

wings level mush attitude to impact just short of the rugged

shoreline.

Total airtime was less than10 seconds. Shoreline witnesses

stated that the aircraft appeared to descend very steeply then it

disappeared in the splash. One witness thought the aircraft had

crashed and ran to contact rescue authorities. The aircraft

remained afloat and was towed back to its base.

FACTUAL INFORMATION

- The aircraft, manufactured by Quad City Ultralight Aircraft

Corp. (QCU), was powered by a Rotax 503, two-cylinder, Dual Carb,

Dual Ignition, two stroke engine rated at 52 horsepower at 6600

rpm.

- The aircraft was fitted with the 60 inch propeller and HEGAR

re-drive using a Gates PowerGrip

HTD® (High Torque Drive) 960-8M-50 belt.

-The HTD reduction drive belt was found completely devoid of

all of its *cogs.

-The reduction drive belt had been in service 2 years with a

total of 83 hours logged on it.

-QCU recommends belt replacement after 100 hours or one year in

service.

-The belt tension and condition was inspected by the

owner-pilot prior to the flight and appeared to be "tight" and in

pristine condition.

- The aircraft underwent a 50-hour inspection by an AME 10

operating hours prior to the event. The inspection included the

condition, tension and integrity of the belt.

-The aircraft was inspected after the event and no structural

damage was found.

-The PuddleJumper floats were examined after the event and no

damage was found.

-The belt tracking was found to be accurate.

-The drive sprocket did not exhibit evidence of excessive of

wear.

-Except during flight, the failed belt had not been unduly

exposed to environmental elements. The aircraft was either

hangared or an engine cover was used.

-An expert examined the failed belt (less cogs) and opined that

it did not exhibit evidence of excessive wear, delamination or

deterioration.

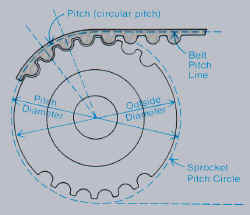

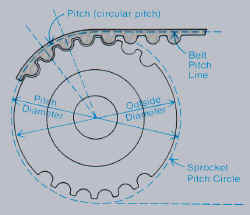

* Note: The PowerGrip System is described by the manufacturer

as providing positive slip-proof engagement by the belt teeth

meshing smoothly with the sprocket grooves. To better understand

this report from a Challenger user/maintainer’s perspective: The

belt teeth are termed "cogs" in accordance with common Challenger

terminology. The sprocket has protrusions which resemble teeth

that extend between the sprocket grooves.

These protrusions are termed "teeth" in this report. The

popular and incorrect belief is that these sprocket teeth drive

the belt. The positive engagement of the semi-circular belt cogs

with semi-circular grooves in the drive sprocket is what drives

the belt. It is therefore essential that the belt be tensioned to

properly seat the belt cogs firmly into the grooves. The sprocket

"teeth" would be better described as spacers between the sprocket

grooves.

RESEARCH

It was found that a substantial amount of information is

available on the care and maintenance of the

|

| An indication of a lose belt |

Rotax 503 aircraft engine. Specific information on the Challenger

reduction drive belt inspection, tolerances, system components,

serviceability, tensioning procedures, tension values and belt

care is sparse to non-existent.

When a drive belt fails the loss of thrust is instantaneous and

virtually without warning. Drive belt failure, unlike a number of

engine failures, provides no obvious warning of an impending

failure except through detection during knowledgeable pre-flight

belt drive inspection. Information on the care and handling of

belts prior to installation was also found to be sparse to

non-existent.

Warnings not to mishandle (crimp) the belt are placed on one

particular equivalent brand of belt in 5 languages. There was no

such warning o n the failed belt. The normal fashion for a

synchronous belt to fail is by loss of cogs. Any other failure is

abnormal. The shearing of belt cogs can be caused by excessive

shock loads applied to the belt. Belt performance is generally

unaffected in ambient temperature environments of -30F to 185F.

Belt cracking can occur under extreme low temperature start-up.

If a belt is removed and reinstalled to run in the opposite

direction accelerated wear will result from a mismatch of the

established wear pattern. Synchronous belts are not date stamped

and have a shelf life of 8 years without a reduction in

performance.

One manufacturer’s policy is to not ship drive belts to

suppliers more than 5 years after belt manufacture. A mandatory or

suggested belt in-service life imposed by manufacturers was not

found. Instructions supplied with the re-drive state the belt

should last 200 hours or more but recommends replacement after 100

hours or 2 years in service.

During industrial application GT belts reportedly achieved a

service life of several thousand hours prior to routine

replacement. GT2 belts have not been on the market long enough to

establish a service life profile. Synchronous belts continue to

evolve with material technology and construction design. The first

generation (1988) Gates PowerGrip HTD® belt subsequently evolved

into an improved PowerGrip GT® version.

The GT belt has a modified cog profile resulting in complete

cog flank contact that eliminated stress

|

| An indication of a loose belt. |

concentrations and cog deformation under load. This greatly

increased belt life and resistance to ratcheting. The Gates

PowerGrip GT2® version was introduced in February 2000. The GT2

belt features a longer and more robust life and with its

redesigned deep cog profile is capable of transmitting up to 200%

more power than previous PowerGrip GT and PowerGrip HTD belts.

When tested against competitor belts at sprocket speeds up to

9000 rpm the GT2 belt outlasted the competitor belts more than two

to one. As patented belt designs expire numerous generic versions

enter the marketplace. There are presently at least 12 different

brands of synchronous belts on the market. A recently introduced

belt features a small lateral groove along the face of the cog.

The purpose of the groove is to allow the release of trapped

air and to reduce noise generation. QCU, the manufacturer of the

Challenger Ultralight was requested to provide the research data

or to provide the foundation for the imposition of their 100-hour,

one-year in-use limitation placed on the re-drive belt.

The stated belt limitations imposed b y QCU in the Challenger

50 Hour Inspection Report was found to be arbitrary and without

foundation. The QCU imposed belt limitations remain unchanged

despite technological advances in belt design and durability.

The 880 8M 85 synchronous belt used on the Zenair 601 is about

an inch wider and 6 inches shorter than the 960 08M 50 belt used

on the Challenger. Belt life is projected to be a minimum of 500

hours of operation utilizing a Subaru 100 hp 4-stroke engine at

4500rpm. While utilizing pre-G2 belt technology and design, Zenair

belt usage to 850 hours is commonplace in applications up to 200

horsepower.

There is no specific calendar limitation imposed on the belt.

One reported premature belt failure occurred with indications that

the belt was not tensioned or tracked correctly. Information on

belt tensioning procedures is apparently not provided with the

re-drive system.

"V" belts depend on friction to transmit power. V-belt

applications such as that used on the Challenger cooling fan

sustain normal wear during service and become "loose". The common

perception that fan belts stretch with wear is only partially

correct. The belt shoulder is compressed, burnished and worn

during use causing the belt to become thinner and hence "looser"

on the pulley.

If the Challenger pulley is not compressed through shim removal

the belt will eventually slip in the pulley while under load. A

Challenger fan belt with 150 hours logged in service was examined

and found to be virtually the same length as the new replacement

however the used belt was 2 mm narrower at the shoulder.

Synchronous belts function under a different principle than

V-belts. The synchronous belt itself may wear and stretch only

minimally. It is absolutely essential that the prescribed

pre-tension value be maintained as well as the system drive

sprocket integrity and sprocket alignment (tracking).

The pitch of the belt is the distance between the center of

each cog measured on the pitch line (circular pitch). The

Challenger belts have an 8mm circular pitch. If the belt stretches

with age and use there is a corresponding belt pitch change. The

pitch change allows a mismatch to be generated between the face of

the sprocket groove and the driven side of the belt cogs. The

mismatch creates increased friction between the two surfaces thus

accelerating cog wear and sprocket wear.

Evidence of this wear manifests itself at the driven shoulder

of the belt cogs and at the shoulder of the drive sprocket groove.

In extreme cases, evidence of belt facing material may be

exhibited on the drive shoulder of the sprocket grooves.

Over-tensioning the belt can impose higher than design bearing and

shaft loads and leads to reduced belt and bearing life. When the

belt is severely under-tensioned an inherent self-tensioning

characteristic is generated by belt circumferential force against

the sprocket grooves.

Since the groove face is inclined, the belt slides up the

groove while under load which in turn increases overall belt

tension. The increased tension leads to increased stress on the

cogs, accelerated cog wear and reduced belt l ife. The sprocket

groove and cog combination will take the path of least resistance

and the cogs will ride high on the sprocket grooves and teeth or

even ratchet by them while under high torque load such as during

take-off.

In due course the drive sprocket will either damage or shave

off belt cogs in just a few revolutions of the belt. Ideal belt

tension is the lowest amount that properly seats the belt in the

sprocket grooves during maximum loading at all points around the

drive.

One method for measuring the ideal tension employs a sonic

measuring device the size of a cell phone. This device operates on

the transverse vibration of strings theory which holds that a

belt, when strummed like a guitar string, vibrates at a specific

natural frequency based on its tension, mass and span length.

During research into this event the formula to calculate belt

drive pre-tension values was entered into a computer using the

manufacturer’s engineering software. The engineering formula was

entered into the computer using the application data of a Gates

PowerGrip 960-8M-GT-50 belt driving an industrial ventilator

propeller powered by a Challenger engine using re-drive

parameters. (Gates does not endorse application of its product on

aircraft).

Using a 30 tooth, 3.01 in. DriveR sprocket and a stock 80 too

th, 8.02 in. DriveN sprocket (the Challenger uses a 78 groove

DriveN) with a 10 inch center distance the computed slack side

belt deflection was 0.150 inches (about 5/32in.) with an applied

belt deflection force of between 27.52 and 29.39 pounds for a new

belt and 23.78 to 25.65 pounds for a "used" belt.

The computed sinusoidal wave frequency, or Sonic Tension Value,

for a properly tensioned used (Challenger) GT belt is between 156

and 163 Hertz. Also determined was a handy rule-of-thumb

tensioning method which could be used by Challenger owners: The

belt, at mid-span, should deflect 1/64ths of an inch for each inch

of belt span at about 28 pounds force for a new belt and 24 pounds

for a used belt. The Challenger belt span is about 10.25 inches

which amounts to about 3/16ths of an inch cold belt deflection

measured on the slack (exhaust side) span.

Synchronous belts cannot be run at unlimited speeds and power.

The limitation of a synchronous belt drive system is the sprocket

"Rim Speed" which is almost identical to the belt speed. This

speed limitation is 6500 feet per minute (fpm) which is much

greater than speeds the Challenger 7075-T6 aluminum drive sprocket

attains at full power.

Above 6500 fpm speeds standard cast iron sprockets can develop

cracks and fracture. The actual "belt" limitation of a drive

system relates to the tension imposed on the belt by the drive

horsepower. The PowerGrip GT2 belt carries a rating of over 120hp

at a 6500fpm Rim Speed. A random Challenger take-off engine RPM of

6300 was selected and entered into the computer using a 30 groove

drive sprocket and a custom 78 groove DriveN sprocket.

The following was determined:

Rim Speed 4927 fpm with a prop Speed of 2423 rpm and a 633lb.

belt pull (Belt Shaft Load). At a take-off RPM of 6500 the Rim

Speed is 5084 fpm and a prop speed of 2500 rpm is attained. A new

GT belt was installed on the incident aircraft and pre-tensioned

to 3/16in.

The belt felt much tighter than the owner-pilot was accustomed

to during his previous pre-flight belt inspections. Because the

belt felt "too tight" for bearing li fe, the rule-of-thumb

deflection was increased an additional 1/16in. to 1/4in. The

maximum engine rpm attained after installation of the new belt was

about 200 rpm more than the average maximum attained prior to the

belt failure.

ANALYSIS

The tachometer rpm fluctuations observed by the pilot during

lift-off were caused by ratcheting and/or the initial failure of

the first belt cog or cogs. Each revolution of the belt

transported the cog-damaged sector toward and past the lower

engine sprocket drive.

The

engine momentarily increased rpm due to lack of shaft resistance

until cogs were again in contact with the sprocket drive

grooves/teeth. The tachometer rpm indication momentarily increased

and decreased each time the cog damaged or cog-free sector of the

belt was transported past the sprocket drive. With each revolution

of the belt, the cog-damaged sector was enlarged by the

over-speeding sprocket drive that damaged or shaved off more cogs.

Finally the damaged sector was large enough to allow the engine

sprocket drive speed to exceed 7000 rpm. The

engine momentarily increased rpm due to lack of shaft resistance

until cogs were again in contact with the sprocket drive

grooves/teeth. The tachometer rpm indication momentarily increased

and decreased each time the cog damaged or cog-free sector of the

belt was transported past the sprocket drive. With each revolution

of the belt, the cog-damaged sector was enlarged by the

over-speeding sprocket drive that damaged or shaved off more cogs.

Finally the damaged sector was large enough to allow the engine

sprocket drive speed to exceed 7000 rpm.

All the remaining cogs were instantly shaved off when they were

transported to the high-speed sprocket drive; akin to the action

of a wood router. It was at this time that all thrust was lost.

From start to finish the process took less than 3 seconds. The

increase in maximum engine rpm attained following installation of

the new belt was evidence of the previous belt’s mismatch between

the cogs and the drive sprocket grooves due to belt pitch change.

The mismatch created additional friction that absorbed engine

torque. The float-equipped aircraft was at low altitude, in a

shallow nose-up attitude, in high drag configuration just above

the stall speed when thrust was lost. (The dead man’s curve). The

aircraft rapidly decelerated into the stall regime. Insufficient

height existed to lower the nose to effect a classic stall

recovery.

Fortunately, the Challenger’s stall characteristics allowed the

aircraft to mush with substantial elevator and flaperon authority.

As a consequence, the pilot had adequate lateral and pitch control

throughout the steep descent until splashdown.

Had the Challenger possessed classic aircraft stall

characteristics the nose would likely have dropped during the

stall and in all probability the tip or tips of the floats would

have dug in at impact causing the aircraft to flip inverted.

FINDINGS

1) The engine driven reduction belt failed under high torque at

a critical moment during take-off.

2) The lower than optimum engine rpm prior to the occurrence

was evidence of excessive belt friction.

3) The belt failure was caused by inadequate tensioning of the

belt.

4) The failed PowerGrip HTD belt was an earlier, less robust

version of current PowerGrip GT belts.

5) Synchronous belt manufacturers’ prescribed belt-tensioning

values and procedures are not readily available to aircraft

owners, pilots and maintainers.

6) The pilot was unaware that minor tachometer rpm fluctuations

to above normal values at take-off power indicated imminent belt

failure and total loss of thrust.

7) The one-year, one hundred hour service life imposed by QCU

on the Challenger synchronous belt is arbitrary and without

foundation.

8) For liability considerations the Gates PowerGrip belt

application on the Challenger (and other) aircraft is not endorsed

by Gates Rubber Company.

9) Direction of rotation should be identified on the belt and

that direction should be maintained for the life of the belt.

10) The Challenger aircraft’s docile stall characteristics

averted a potentially serious accident.

Flight Safety Suggestions for Challenger Owners, Pilots and

Maintainers.

-Discard any old drive belt or those marked "PowerGrip HTD"

regardless of the belt’s service life.

-Preflight, examine the re-drive belt tension to ensure it does

not exceed ¼" deflection. (Apply tension pressure with your thumb

till it hurts, you then have about 25 pounds pressure).

- When measuring the belt deflection pull the propeller

backward against engine compression to slacken the belt’s slack

side.

-Preflight, rotate the propeller and examine all 120 belt

"cogs" for excessive wear or damage.

-Preflight, tap or pluck the belt, if it doesn’t vibrate its

probably too loose.

-Periodically examine the belt’s neoprene backing for hairline

lateral cracking. Cracking is detected most easily where the belt

backing is stretched around the lower drive sprocket.

Alternatively, examine it around the upper sprocket.

-If any belt damage, excessive wear or cracking is found

replace the belt immediately.

-Always use smooth throttle handling to reduce the risk of

shock load failure.

-If practical, protect the belt from moisture, chemical

contaminants and direct sunlight. With proper care and maintenance

the GT belt should provide at least 5 years and 500 hours of

Challenger service. The GT2 belt should provide at least 5 years

and 700 hours of service. Four JPG photographs are attached

showing, for comparison, a new belt and the failed belt,

belt/sprocket specifications and a suggested belt tensioning

procedure.

Picture summmary

A. New and failed belt.

B. Belt pitch length is measured along the belt pitch line.

C. Preparation to measure belt deflection.

D. Prevent belt twist and apply pressure.

(Note about ¼ inch deflection. )

Editors Note.

The author spent 23 years as a professional Aviation Safety

Investigator (Canadian Aviation Safety Board) and Aviation Safety

Consultant (Accident Investigation & Research Inc.) His

professional responsibility during this period was to identify

aviation safety deficiencies. Determining "WHY" the event happened

or "WHY" a component or system failed is part of that process.

The thrust of this Challenger flight safety report was to

determine "WHY" the belt failed and to educate Challenger users

about the synchronous belt application on their aircraft.

Dissemination of this report to Challenger users will hopefully

prevent a recurrence of an event that had potentially disastrous

consequences. A draft copy of this report was distributed to the

owners of National Ultralight Inc., the exclusive Canadian

Distributor of the Challenger. They declined to comment.

|

The

engine momentarily increased rpm due to lack of shaft resistance

until cogs were again in contact with the sprocket drive

grooves/teeth. The tachometer rpm indication momentarily increased

and decreased each time the cog damaged or cog-free sector of the

belt was transported past the sprocket drive. With each revolution

of the belt, the cog-damaged sector was enlarged by the

over-speeding sprocket drive that damaged or shaved off more cogs.

Finally the damaged sector was large enough to allow the engine

sprocket drive speed to exceed 7000 rpm.

The

engine momentarily increased rpm due to lack of shaft resistance

until cogs were again in contact with the sprocket drive

grooves/teeth. The tachometer rpm indication momentarily increased

and decreased each time the cog damaged or cog-free sector of the

belt was transported past the sprocket drive. With each revolution

of the belt, the cog-damaged sector was enlarged by the

over-speeding sprocket drive that damaged or shaved off more cogs.

Finally the damaged sector was large enough to allow the engine

sprocket drive speed to exceed 7000 rpm.