|

ROTAX MANDATORY SERVICE BULLETINS

SB-912-032 (912A Series) and SB-912-032UL

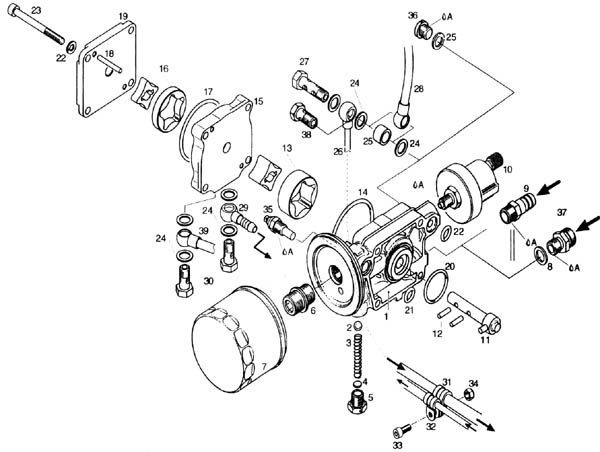

"REPLACEMENT

OF OIL PUMP ASSY OR OIL PUMP SHAFT ASSY

The following MANDATORY service bulletins

required by Rotax to be incorporated at "at the next 100 hourly

inspection" but "at the latest by 1 Feb 2002" have been received

from Rotax. They affect certificated and Ultralight 912 Engines

and can be viewed by clicking the following links. These also give

serial numbers of engines affected.

SB-912-032 (912A Series)

SB-912-032UL (912UL Series)

To all Rotax 912 owners: Oil Pump Drive Pin

Following is the text of correspondence

forwarded to the AUF some time ago by Mr Carl Nilsson from

Tasmania.

Mr Nilsson's Correspondence:

In May 1999 my Skyfox CA22 reg. 55-0688

suffered an Rotax 912A engine failure and consequent forced

landing with no injuries, but some aircraft damage. This was

reported to the AUF and a brief summary of the accident appeared

on p 44 of the July 99 AU. What was noteworthy was that the

engine, No. 4076033 had only 26 hours since major overhaul. After

starting to lose power, the pilot continued to run the engine

until it seized. In fact, the crankshaft was destroyed and the

engine was a write-off. The cause was failure of the oil pump,

specifically the shearing of the dowel tube follower that drives

the oil pump. When this happened, the oil pressure would have been

lost and total engine failure followed.

Now, the message of this report is firstly, if

you are running an older Rotax 912 of serial number between

3792944 and 4076068, you should read the following story and check

that oil pump drive pin (follower). I purchased 55-0688 from **

Aviation in late 1998 with the engine having about 2140 hrs TTIS

and running well enough, but clearly needing an overhaul in the

near future. I flew the aircraft to Victoria with no trouble and

subsequently arranged an overhaul with a very competent Level 2

engineer.

The history of the engine was not fully

documented in the log book. It had been maintained for at least

the latter part of its life by a GA service organisation (Flinders

Aviation) and at some stage it had had a top end overhaul,

possibly when it was installed in 55-0688 with 935 hrs TTIS.

Someone had also honed the cylinders - a common practice with GA

engines, but a real no-no with the Rotax 912, which has Nikasil

coated cylinders. These things were apparent to the overhauling

AUF engineer. Now, owners of older 912's may note that certain

work had to be completed at 600 hrs to extend the TBO to 1000 hrs.

Rotax Technical Bulletin (TB) 912-05R2 refers for all 912A's

(Certificated) and earlier than N. 4076192 (and

Service Information 27 UL 94-E for non-certificated engines

which in return refers back to the bulletin for the certificated

engines). This is an important TB and central to the failure of

engine N. 4076033. (Downloadable from the links above in this HTML

version or available from the table from where you obtained this.

Note that they are large downloads of about 750KB).

Page 5 of this TB details oil pump amendment

nos. 17, 22 and 32-17. These say, essentially, inspect the oil

pump components for wear and, if necessary, renew. There is also a

Note, which says that after engine N. 3792944, the oil pump

capacity was increased by a change of components. It also says,

that after N. 4076068, the hollow drive pin was changed to a solid

notched pin. Thus, engines between N.3792944 and N. 4076068 were

delivered with larger oil pumps, but the original hollow drive

pin. With the wisdom of hindsight, a prudent reading of this

suggests that it would be a good idea for engines within this

range to have the hollow drive pin replaced with the later solid

one, however Rotax does not explicitly direct that this be done.

All they say is: "At a renewal of components change oil pump to

the version with the 16 mm long rotors" - ie. larger capacity. I

can also say that Bert Flood, for example, routinely changes to

the solid drive pin when he is doing a 1000 hrly on a 912.

Now the plot thickens a little: a perusal of

the log book for this engine shows an entry "TB 912-05 complied

with". A normal reading would suggest to an owner (as it did to

me) that these things had been taken care off. It might be, that

at the 600 hr inspection, no oil pump components were changed -

or, it might be that they were at some time, but (clearly) not the

oil pump drive pin. When we overhauled the engine in early 1999,

the hollow pin was looked at, deemed OK and left in situ. When it

failed, this pin had presumably driven the oil pump for about 2200

hrs. After this accident, other owners of 912's at the local

airfield inspected their oil pumps. One Gazelle, which had been

maintained as a GA aircraft, had the usual log book entry "TB

912-05 complied with", but still had the old hollow pin. Another

earlier engine, N. 4005313, which had previously had a 1000 hrly

by Bert Flood, had the solid drive pin as he had stated it should.

So the lesson is - if you have a Rotax 912

earlier than N. 4076068, check the oil pump drive pin and, if it's

hollow, replace it

Carl Nilsson AUF 009966.

Tech Manager Comments. A sad occurrence

stressing the need for vigilance in airworthiness management. The

information that would have prevented the occurrence had been

published as far back as 1995/96 in Rotax Service Data. However,

one having been caught out suggests that it should be brought to

the attention of all members.

|