Rotax 618, Rotax 618 Rave valve parts, Rotax rave valve maintenance procedure. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

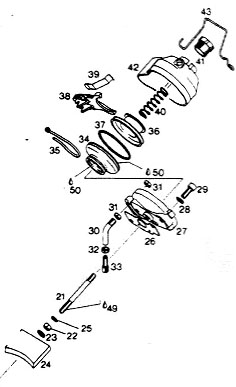

Rotax Rave valve maintenance and cleaning. The Rotax 618 uses a system called RAVE to adjust the power output of the 618 engine at lower engine rpm., and like anything that moves up an down in a channel, which is effected by heat, and oil it requires maintenance and cleaning to work properly.  The 618 Rotax uses the spent exhaust gasses to open and close the RAVE valve, which is a simple guillotine style of valve. A small hole in the exhaust port applies pressure to a set of bellows, under load or at high revs the back pressure pulls the guillotines up and down adjusting the back pressure of the exhaust system. At lower rpm a spring is used to keep the valves closed. If the valves are stuck open or closed they can effect the 618 in lower or higher rpm settings. If your engine revs fine at full power but is sluggish at the lower end then your valves are sticking open - not giving enough back pressure to the system. If your engine is not putting out full power at top end but run fine from at an idle they there is a good chance your valves are sticking in a closed position, or failing to open all the way up. Cause: The major causes of sticking RAVE valves on the 618 Rotax engine are the type of oil used and the pitch of the propeller. Oil - The RAVE valve system requires oils with a "high flash point," which refers to the temperature that an oil ignites at. Higher flash point oils are less prone to leaving oily residue on the guillotines, residue that builds up, hardens, and prevents proper valve action. Too much oil is another problem. The 618 uses an oil injection system, to help prevent excessive oil input into the engine it is essential that the oil pump be set up properly. Storage: Many of our craft get stored for periods of time. During these storage periods it is essential that the engines be stored properly. With fuels drained and engines lubricated. Propeller: The next major contributor to oil build up is the propeller. Too much pitch in a prop will lug the engine down, causing excessive build up in the RAVE valve system. The 618 likes to rev and Rotax recommends a setting of 7200 rpm full power straight and level flight. This can usually be set up by achieving 6800 tied down on the ground. Cleaning: The RAVE valve system is not complicated, but attention must be paid when disassembling and reassembling the unit. A parts manual, and Polaroid pictures during disassembly are recommended. To remove the RAVE valve unsnap the retaining spring (43), remove the cap (42), being careful not to loose the compression spring (40) use a 10 wrench or socket, to remove the nut (41) on top of the rave valve stem (21), remove bellows, (34, 36, 37) use an allen wrench to remove two allen bolts, remove housing with valve assembly. When you have the slides out inspect them for carbon deposits. If present remove them with a find wire brush and cleaning solvent. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Rotax 618 Rave valve maintenance. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Ultralight Aircraft News Web Magazine EMAIL for l Information. No part of this publication may be copied or distributed, transmitted, transcribed, stored in a retrieval system, or translated into any human or computer language, in any form or by any means, electronic, mechanical, manual, or otherwise, without written permission of Ultralight Aircraft News. By copying or paraphrasing the intellectual property on this site, you're automatically signing a binding contract and agreeing to be billed $10,000 payable immediately. Copyright Ultralight News EMAIL | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Return to Main Index for this section | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||