Parts for Rotax 447 aircraft engine.

|

|

|

|

|

|

|

|

|

|

Click on arrow to move through manual or

store. |

|

|

|

Click here to go to

Home Page. |

|

|

|

Rotax intake socket 377, 447,

503 |

|

|

|

Rotax 447 fan belt Rotax engines |

|

|

Click here for more information on

fan belt, fan belt tools and adjustment. |

|

Dual

fuel pump 994 485 Dual

fuel pump 994 485

It is recommended that all Rotax engines use the dual fuel pump

supplied by ROTAX. There is a

difference between the pump used in snowmobile/motorcycle/seadoo

and aircraft.

When using the pump on a single carb engine "T" the two lines

together. Make sure to isolate the fuel pump from heat and

vibration.

The pulse line should be no longer than 12 inches Pumps should not

have to lift fuel any more than 24 inches.

Click here for more information!

|

|

|

Rotax aircraft engine parts |

Points

- 2 sets required, replace as necessary if found worn, or damaged. Points

- 2 sets required, replace as necessary if found worn, or damaged.

Remember to lubricate phenolic blocks.

Check point gap within 10 hours

of new point installation, and ignition timing.

|

Condensers

-

2 required, replace as necessary if found to be damaged, oil soaked, loose fitting or

defective.

Threaded 964 219 Condensers

-

2 required, replace as necessary if found to be damaged, oil soaked, loose fitting or

defective.

Threaded 964 219

|

|

NGK Spark BR8ES plugs

The proper spark plug for use in

most of the Rotax engines is the NGK B8ES, or other brand name

equivalent, (Champion spark plugs are not recommended, nor are

they factory authorized for ultralight

use.)

If using a spark plug with an BR

in its heading, (usually used for ignition noise suppression) such

as NGK BR8ES, a resistor cap should not be used. This is because

of the double resistance supplied when using both a resistor plug

and resistor cap. It is advisable with engines running in the

inverted position to use a spark plug with an extended electrode.

This aids in stopping spark plug fowling. Look for a BP in its

heading (NGK BP 8ES).

When removing or installing the

spark plug cap make sure that the cap is turned, in the rotation

necessary to tighten the screw on cap on top of the spark plug,

otherwise the improper removal of the cap results in the backing

off of the screw on cap and the possible loss of spark to the

engine, when the spark plug cap falls off.

Also see resistor plugs vs. resistor caps!

The recommended gap on the spark

plugs is .015 to .019 of an inch. These plugs are capable of running for

over 20 hours trouble free on a points and condenser engine and up

to 50 hours trouble free on a dual CDI ignition engine (if proper

fuel and oil are used and the engine is in proper tune). They

should be checked on a regular basis however, and replaced at the

first sign of a miss or after severe flooding of the engine.

If using a cylinder head temp

gauge, removal of the ring on the bottom of the spark plug is

recommended, since the gauge sending unit replaces it. (Cylinder

head temperatures should range in the 300 to 400 degree F range.)

In practice, a properly tuned

engine should show a nice chocolate, or brown color on the spark

plug, white indicates an engine running hot, while black indicates

one running to rich. Any sign of aluminum on the spark plug

indicates a problem of a very serious nature, and requires your

immediate attention!

Also see "How

to read your spark plugs" |

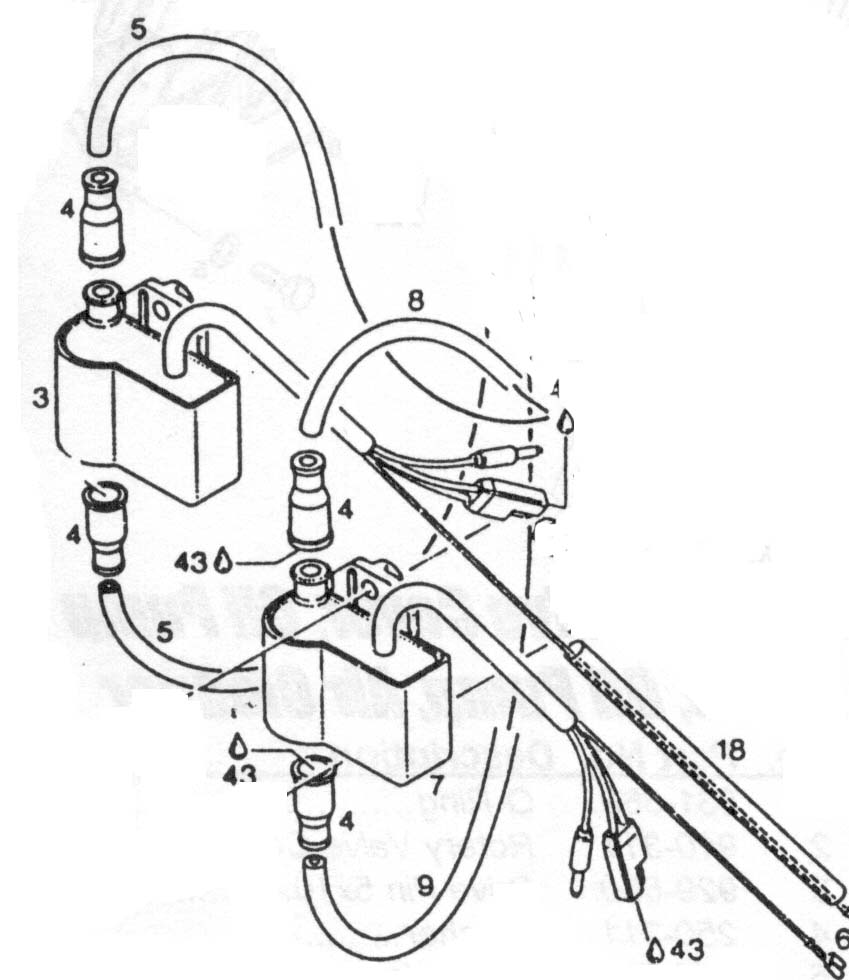

Electronic box assembly

3-6 965 4217-9

966 320 |

|

|

Rotax Bosch ignition coil for Rotax aircraft engines

A regular replacement item. Suggested

replacement every 150 hours, or at the first sign of coil failure.

When installing new coils on twin cylinder engines note coils are wired #1 coil is pole 1

to ground while 15 is to points. #2 coil is wired 1 to points and

15 to ground.

When routing ground wire lay it flat against coil so wire does not

bend back and forth in the wind-which could cause wire failure and

loss of ground.

Also make sure bolts are reinstalled using blue Loctite, or they

will come out - these holes use self tapping bolts, without

Loctite they will come loose, causing loss of ground, which will

result in loss of ignition, or or coil.

|

|

|

|

|

Rotax Circlip all Rotax

2 stroke |

|

|

|

|

|

Rotax Pistons |

|

|

447 Standard Rotax Piston

with rings |

|

|

|

1st over447 Rotax Piston

with rings |

|

|

447 2nd over Rotax Piston

with rings |

|

|

|

Rotax 447 Rings - bottom ring |

|

|

Rotax 447 Rings -top ring |

|

|

|

|

|

|

Rotax 447 Engine Rebuilding Video

Rotax engine rebuilding videos, each video is approximately 2

hours in length and takes you step by step through the tear down,

clearing, and reassembly of a Rotax engine |

|

|

|

Click here for Rotax engine and gear box prices! |

|

|

|

|

|

Ultralight News Web Magazine .-.-.-.

. No part of this publication may be

copied or distributed, transmitted, transcribed, stored in a

retrieval system, or translated into any human or computer

language, in any form or by any means, electronic, mechanical,

manual, or otherwise, without written permission . By copying or paraphrasing

the intellectual property on this site, you're automatically

signing a binding contract and agreeing to be billed $10,000

payable immediately. Copyright Ultralight News -

Ultralight Flyer. . |