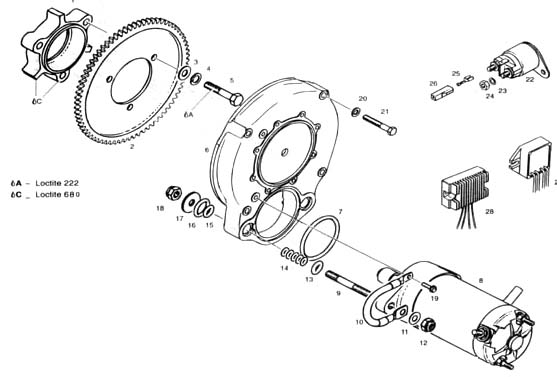

Rotax 377 electric starter and regulator rectifiers. |

|

|

|

|

|

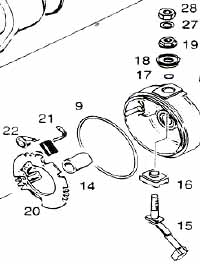

Rotax 377 electric starter

|

MESK1 Rotax Factory Starter 377-447-503 |

|||||||||||||||||||||

|

MESK2 Rotax Factory Starter 532 |

|||||||||||||||||||||

| MESK3 Rotax Factory Starter 582 | |||||||||||||||||||||

|

Things you should know when using or installing

an electric start. Several electric starters are available for the Rotax line of engines. The only one that I recommend is the Rotax supplied starter. For more information click here. The starter should be used with a minimum 20 amp hour battery. The battery leads should be no more than 5 feet in length. and a separate ground cable must be run to the engine from the airframe, to ensure proper ground. Several owners have reported burning up their engine wiring system when they failed to follow instructions and properly ground the engine. This is caused by the single small ground wire that is grounded to the coil mounting bolts, melting in the wiring harness, fusing wires together when the engine is cranked. This wire is not large enough to carry the kind of current necessary. When using an electric start on a Rotax aircraft engine TWO grounds are required, one going from the engine to the airframe and another going from the engine to the negative side of the battery. These ground cables should be about the same diameter as that used on a GOOD set of booster cables, that you would use to jump start your car. (In many cases that is what pilots have used). Other pilots have reported failure of the starter solenoid supplied with the Rotax starter. It would appear that this failure is caused by improper mounting of the solenoid. The solenoid should be mounted in free air away from vibrations, and as close to the engine as possible. I don't even recommend using the solenoid that is USUALLY supplied with the starter from Rotax. Instead drop into your local Canadian Tire store or a good automotive supply center and get a solenoid for a Ford car, or truck. It can usually be found on the fender. I have never had one of these fail and it can be purchased locally. Another reported problem with the starter is the failure of the studs used to secure the starter to the ring gear housing. If your starter is mounted in any position other than the 6 o'clock position failure of the stud will result in the two big washers found on the end of the stud falling into the magneto. The washers are then picked up by the magnets with catastrophic results. Usually destroying the crankcases and ignition system.

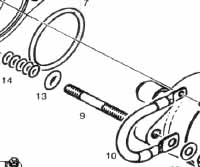

To help prevent this it is suggested that the starter only be mounted in the six o'clock position. If the studs break in this position the washers would fall harmlessly to the ground. However I also suggest that you run a bead

of silicone from one If you have had to replace the studs, or

have done other work which requires removal of the starter motor,

remember that there is suppose to be a TWO milli meter gap between

the starter and ring gear housing. Rotax has also updated the ring gear on the electric start the new gears are slightly thicker. The older gears were found to crack and fail around the gear teeth. Rotax also updated the spacer used to support the ring gear. The older spacers only had three support fingers while the new supports have five support fingers. Some owners have reported finding their ring gear housing breaking at the point where the stud runs through the housing. This can usually be traced to a succession of hard landings, or to the starter striking something on the airframe during acceleration. The only other problem I have heard of is slow cranking starters, or starters that will no longer crank. This problem can be traced to the starter brushes. One brush can be replaced easily The other requires the purchase of the complete plate assembly.

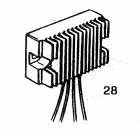

While not an electric start problem, the use of the proper regulator rectifier on the 582/618 can lead to the battery going flat, and the electric start not working. While the points equipped can use the CHEAPER regulator rectifier the 503/582/618 Ducati ignition engines require the use of the more expensive regulator. The reason for this is that the the NEW 503/582/618 put out considerably more charging power than the old 377/447/503's 532's. This translates to more HEAT in the regulator/rectifier. The more expensive regulator/rectifier is larger and has aluminum fins which are used to dissipate this heat.

|

|||||||||||||||||||||

Ultralight Aircraft News Web Magazine EMAIL for l Information.

No part of this

publication may be copied or distributed, transmitted, transcribed,

stored in a retrieval system, or translated into any human or computer

language, in any form or by any means, electronic, mechanical,

manual, or otherwise, without written permission of Ultralight Aircraft News.

By copying or paraphrasing the intellectual

property on this site, you're automatically signing a binding contract

and agreeing to be billed $10,000 payable immediately. Copyright Ultralight News